When I decided to make my own DIY guitar effects, I was totally lost about the tools that I needed: what do I need to build guitar effects? How much does a good soldering iron cost? And what is a good soldering iron? Where can I buy all that?

In this post, I will try to answer all these questions that we ask ourselves when starting. Lets focus on tools! 🛠️

Soldering can be a pain if your soldering iron is not powerful enough: pins of 3PDT, lugs of jack inputs... all necessitate quite a high amount of heat to solder properly. This is why I recommend an at least 30W soldering iron. A high quality iron will also have a more resistant tip, which make it longer lasting.

Beware! I put links to amazon US, so the electrical tools will have a 110-120V plug!

You can also look for second hand tools, there are sometimes very good deal, especially for soldering stations.

EDIT: unfortunately it is not available anymore... But Weller is again your friend. This one is top notch

You can still find lead solder online. Your choice!

Here are two examples of wire strippers:

A "needle nose" pair of pliers can be really useful to tighten bolts of the different parts we use: potentiometers, jacks, 3PDT switches...etc.

Finally, you will need a screwdriver for tightening enclosures, setting trimpots...etc A multitool like this one can work.

However, as a drill can be really useful in your daily life, you can also choose to buy a good model that will last and will be used for other things than guitar pedal making 🔨

For drilling guitar pedal enclosures, a drill press is simply awesome. However, you might not want such an industrial equipment in your living room like me 😅

Here are some example of drills you can use:

There it is! You have got all you need for guitar pedal making! If you take really basic stuff each time, it can cost you around 70$ only! Lets now see "non necessary but helpful" tools that you might need from times to times.

Here is a nice set of electrostatic tweezers. Electrostatic is a plus if you use them for SMD soldering for instance.

To be honest, the magnifying glass is useless, even for SMD. But it makes the third hand look a bit like a helping little fellow, which is nice. I use it from times to times, but not a lot.

In this post, I will try to answer all these questions that we ask ourselves when starting. Lets focus on tools! 🛠️

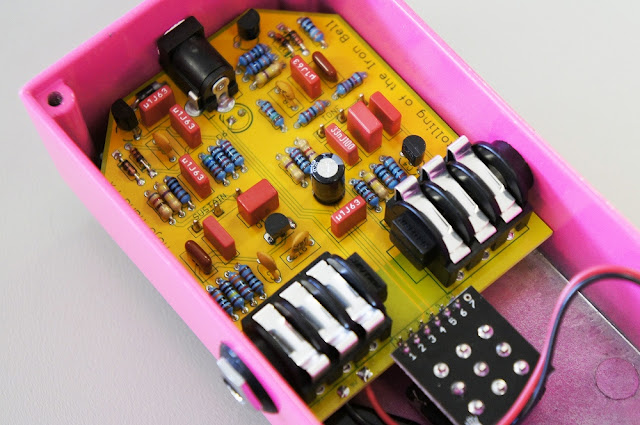

(My bench. It is almost never that clean haha!)

ESSENTIAL tools to make DIY guitar pedals

1. Soldering Iron

Lets start with the most obvious tool that you will need: the soldering iron! It is really important to have a GOOD soldering iron when you start. It will really make huge differences when it comes to soldering. 👍Soldering can be a pain if your soldering iron is not powerful enough: pins of 3PDT, lugs of jack inputs... all necessitate quite a high amount of heat to solder properly. This is why I recommend an at least 30W soldering iron. A high quality iron will also have a more resistant tip, which make it longer lasting.

Beware! Use a pointy tip soldering iron, and not an electrician soldering iron.

You can also look for second hand tools, there are sometimes very good deal, especially for soldering stations.

- Basic soldering iron: a classic soldering iron with a pointy end, with a 30W power minimum. It should work quite well! If you just want to make a few pedals, or if you do not want to spend a lot of money, it is an ideal first companion! Here is an example at $14. Of course, you can also buy this kind of soldering iron pretty much everywhere. Just make sure that it has a pointy end, and a 30W power minimum.

What about adjustable temperature? Adjustable temperature is a nice add on, but not a must. If you work with a small soldering tip, heat will transfer badly, making it more difficult to melt solder. Increasing temperature can be useful in these case. Being too hot can also damage heat sensitive components.

I usually recommend 250°C / 400° Fahrenheit for general soldering. You can increase to 350°C / 650° Fahrenheit for heavy soldering and SMD with a very fine tip.

I usually recommend 250°C / 400° Fahrenheit for general soldering. You can increase to 350°C / 650° Fahrenheit for heavy soldering and SMD with a very fine tip.

- Mid-range soldering iron: you want to make quite a few pedals, or you directly want to invest into quality tools? Weller is a reference in the professional soldering world, and their "professional series" is really, really good. By chance, Weller is really cheap in the US (compared to France), so get one! Here is an amazing soldering iron at $45. It is a professional tool that will last forever. It is pretty expensive, but worth it! No adjustable temperature though.

- Professional soldering station: you want to assemble hundreds of pedals? In that case, investing in a soldering station can be a good idea. I found in love with the amazing Hakko FX888D station. Do not be scared by the "toy" look of the station! For only $99, you get a real professional-grade soldering station. No wonder why so many professional guitar pedal builders use one! You can read my review here.

EDIT: unfortunately it is not available anymore... But Weller is again your friend. This one is top notch

2. Solder

Before, solder was containing lead. It was used because the solder melted easily at low temperature, and was really practical for electronics as you do not want to heat components too much. However lead has been banned for ecological reason and is now forbidden in the EU (with the RoHS norm). 🌳You can still find lead solder online. Your choice!

- Silver or tin? Some people will tell you that silver solders are better. Practically speaking, I did not noticed that much differences when soldering, or for durability. Even in theory, the difference of resistivity is really, really low! Personally, I think it is a waste of money. Moreover, silver can oxidize...

- Diameter? I recommend a diameter inferior to 1 mm. If it is bigger than that, it will be difficult to be precise enough with PCBs for instance. If you plan on soldering SMD, you can sure go for 0.6mm.

- So, what to choose? Usually, I buy mine in a local shop (for mojo points maybe?), but you can find it pretty everywhere. I just saw that lead is still legal in the US, so it is up to you! Here are two nice example: with lead or lead-free solder.

3. Pliers, wire strippers, screwdriver and wire cutting snips

Having wire cutting snips is absolutely necessary to cut wires, component legs. A wire stripper is also really useful to snip wires. No need for amazing technological stuff, you can find these really basic tools everywhere. I bought mine in a local DIY shop, but you can find everything online if you want to. Here is a simple pair of pliers to cut wires and leads.- Here is a simple manual wire stripper, cheap but useful.

- Here is an automatic one, you can set the wire diameter, and it is sometimes easier to manipulate, especially if you have a lot of wires to strip. Your choice!

A "needle nose" pair of pliers can be really useful to tighten bolts of the different parts we use: potentiometers, jacks, 3PDT switches...etc.

Finally, you will need a screwdriver for tightening enclosures, setting trimpots...etc A multitool like this one can work.

4. A drill

To fit your circuits in an enclosure, you will have to drill holes! A drill is thus absolutely necessary. Fortunately for us, aluminum is rather a soft metal, really easy to drill, so you will not need a crazy expensive drill.However, as a drill can be really useful in your daily life, you can also choose to buy a good model that will last and will be used for other things than guitar pedal making 🔨

For drilling guitar pedal enclosures, a drill press is simply awesome. However, you might not want such an industrial equipment in your living room like me 😅

Here are some example of drills you can use:

- The cheap one: I used (and still use...) a really cheap Chinese drill, which cost me around 12 euros (I do not know how is this even possible!), that I bought in a local store. You will surely find other options like this online or in your local DIY shop. Surprisingly, it works really well, and I have no problem with drilling aluminum.

- The expensive / long lasting option: in this case, try to buy a good drill like a Makita. A professional grade drill is a bit more expensive, but will last forever.

- A drill press. As I said before, drill presses are awesome for drilling guitar pedals enclosures. What you need is something with a decent amount of power, at least 350W / 1/2 HP. Variable speed or laser lightnings are a nice touch, but not necessary. An emergency stop button is however a must for me. Here is a good price for value one that will fit your orange enclosures very well 😀 Again, check for second hand! Many small businesses sell their old equipment online and you can find some really, really good deals there.

- Drill bits: I would suggest buying a small number of HSS twist drills for metal drilling, of a few different diameters. A HSS step drill is also really useful. It will allow you drill any diameter you need for the part you are using

Beware! Safety and drills. Never wear gloves with a rotating machine, remove rings and jewellery (especially your watch) to avoid being dragged in the machine. Don't use your hands to hold the enclosure, use a clamp. Close the safety cover with a drill press. Remember: accidents happen!

Safety tip: keep the emergency number close to your drill.

Safety tip: keep the emergency number close to your drill.

There it is! You have got all you need for guitar pedal making! If you take really basic stuff each time, it can cost you around 70$ only! Lets now see "non necessary but helpful" tools that you might need from times to times.

Optional tools for guitar pedal making

Everything listed here is not absolutely essential, but can be really useful. In order to make clear what was really helpful and what was not, I rated each tool on the "nice but not essential" scale. 5 is the max score (essential), 0 the worst (completely useless).1. Tweezers (usefulness: 4/5)

I hesitated to put these in the "essential" section. If you want to hold a component while soldering (and not burn yourself), to bend or maintain a wire precisely, having tweezers is tremendously useful.

Here is a nice set of electrostatic tweezers. Electrostatic is a plus if you use them for SMD soldering for instance.

2. A third hand (usefulness 2/5)

What is a third hand? It is a simple tool with two arms, which allows you to hold parts. Most of the time, there is also a magnifying glass. It can be useful to hold a part while soldering, like a potentiometer, so your left hand is free to hold solder for instance. It can be useful to tin wires also.

3. A desoldering tool (usefulness 4/5)

It is very likely that you are going to make mistakes from times to times, as every human being does. The problem with electronics is that soldering is really easy. However, desoldering can really be difficult, especially if you do not have the good tools... There are 2 cheap tools that will help you (a bit...) to desolder stuff:

- Desoldering braid: this is what I use when it comes to desoldering. You heat it above the solder you want to remove, and once hot, it will absorb the solder. The downside of this system is that it heats up a lot, and you can burn a bit the PCB, or damage the component you are trying to remove... But it is very cheap

, which is nice, and it works!

- Desoldering pump: another useful tool to desolder. I never used it actually, but I plan on buying one because it seems easier to use than desoldering braid. It is a kind of syringe that will absorb melted solder. A simple one like that can do the job. If you are willing to invest a bit, try this amazing pump. It is crazy efficient with the silicon tip and works really, really well!

4. Combination wrench (usefulness 4/5)

Tightening pots, jacks and 3PDT switches with flat pliers can be really annoying on the long run. Especially if you make quite a lot of guitar pedals.

In that case, I would recommend to buy a combination wrench set. With it, you can tight all the mechanical parts of your pedal easily and fast. I use it every time and never regretted the investment!

Here is a nice set of combination wrench. You can find cheaper ones, but low quality tools are really a pain and can be damaged easily. If you are in Europe, Facom is THE brand for such tools, with a life guarantee included. Expensive but you get what you paid for!

Some prefer socket wrench. I think they have a tendency to scratch enclosures so I prefer combo wrench. You can find cheap multitools that will do the job with socket wrench though, wo do as you please!

5. Round file (usefulness 3/5)

Some holes that we need to make while making guitar pedals are quite huge, especially for the power jack. A round file can help to drill these kind of holes, as well as non standard diameters required for LED bezels for instance.

There it is!

That is all I use to make my guitar effects, and it is really sufficient! See? You do not need a lot... If you clone one "boutique" pedal, you should have spare enough money to buy most of it!

Was this post useful? Join the Coda Effects community by liking the Coda Effects Facebook page. You can also follow Coda Effects on Instagram.

To go further:

Nice video from MAKE about electronics tools. Fun to watch!

Geofex guide about starting building effects.